🌱What are we doing about flexible plastics?

Delving into a material that is both a solution and a problem

Happy Monday! Every Monday we suit up and get serious - digging into a climate topic, rounding up the past week’s Good(s) News and sharing updates from across FTF, so you’re never out of the loop.

Only a few weeks to go until we’re in the throws of Recycling Week. In preparation we have taken this week to look at the elephant in the kitchen when it comes to recycling plastics…that flimsy film that we puzzle over taking off or leaving on (I’m pretty sure I should peel them off and put them in the general waste at this point). Read on to find out why it’s taking so long to get recyclability sorted and which brands are beginning to collaborate to tackle the issues.

Greenly has worked with brands like LVMH, HelloFresh, L’OREAL, Lacoste and Huawei. Keen to learn more about how they can help your brand? Check out their website.

> In Focus

Flexible Plastics: The Popular Packaging Solution (with a Recycling Problem)

Flexible plastics are everywhere. If you’ve ever grabbed a snack on the go, ripped open a bag of chips, or peeled back a wrapper on your favourite chocolate bar, you’ve had a close encounter with these ultra-convenient, lightweight packaging formats. In the world of fast-moving consumer goods, flexible plastics reign supreme. From crisp packets to shampoo pouches, these materials are beloved for being strong, lightweight, and fantastic at keeping our products fresh and safe.

They’re the packaging industry’s answer to all sorts of problems—easy to transport, great for extending shelf life, and a big win for companies looking to reduce costs and environmental impact in the supply chain. Flexible plastics are everywhere because, frankly, they’re really good at what they do.

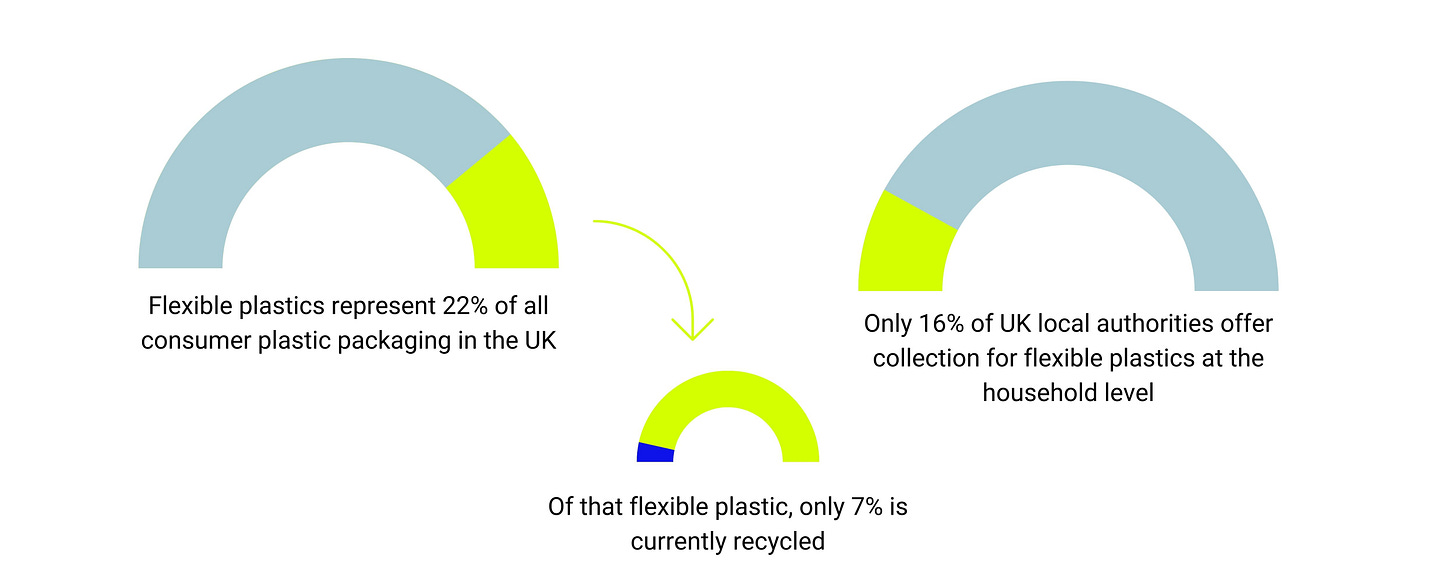

But here's the catch: when it comes to recycling, these flexible wonders are more like that one friend who always promises to show up but never quite makes it. Most kerbside recycling programs don’t accept flexible plastics, and the few that do often struggle with processing them. So, even though we see them everywhere, only a tiny fraction actually makes it through the recycling loop. The rest? Well, they’re often taking a one-way trip to the landfill—or worse, ending up where they definitely don’t belong, like our oceans and parks.

Why are flexible plastics so tough to recycle?

Recycling flexible plastics is not as straightforward as tossing a plastic bottle into the recycling bin. Here’s why these tricky materials keep slipping through the cracks:

Multiple layers: Many flexible plastics are made up of multiple layers of different materials—think plastic, foil, and adhesives all sandwiched together. Separating them for recycling? Not so easy.

Light as a feather: While their lightweight nature is great for shipping, it’s not ideal for recycling. Flexible plastics don’t weigh much, so collecting and processing them isn’t as cost-effective as other, bulkier recyclables.

Messy business: These materials often come with remnants of food or liquids—think greasy chip bags or sticky candy wrappers. Contaminated plastics are a big no-no in recycling, and cleaning them is a hassle.

Breaking point: Flexible plastics have a nasty habit of breaking into tiny pieces during recycling. These fragments can clog up sorting machines, creating chaos in recycling facilities.

Infrastructure blues: Most recycling plants just aren’t set up to handle flexible plastics. They’re designed to deal with sturdier materials like glass or rigid plastic bottles.

Lack of demand: Even when we do manage to recycle flexible plastics, there’s not much of a market for the recycled material, which doesn’t exactly motivate recycling facilities to invest in the process.

The UK’s push to collect flexible plastics

Despite these recycling roadblocks, the UK has slowly started to tackle the problem. Supermarkets like Tesco, Sainsbury’s, and Waitrose are offering flexible plastic collection points in their stores. Now, you can drop off your plastic bags, wrappers, and pouches while you’re out grabbing your weekly groceries. Convenient, right?

These collection schemes have had some success, collecting millions of tons of plastic that would otherwise go to waste. But here’s the reality check: it’s still just a drop in the (very plastic-filled) ocean. The amount collected is only a fraction of the flexible plastics in circulation, and some of what’s collected isn’t always in top shape due to contamination.

But don’t lose hope just yet—The UK Plastics Pact has set a bold goal: by 2025, all plastic packaging should be recyclable, reusable, or compostable. To make this happen, the country is exploring new recycling technologies, like chemical recycling, which could help break down the trickiest of multi-layer plastics. Plus, with the Extended Producer Responsibility (EPR) legislation coming in 2024, FMCG companies will be held more accountable for the packaging they put into the world. In other words, they’ll have to pay up for the waste they create, which should motivate some greener innovations.

There’s a lot of optimism that these initiatives will move the needle, but it’ll take a team effort—government policies, industry commitment, and a little consumer know-how (yes, that means rinsing out those wrappers before recycling).

Learning from global leaders in recycling

The UK isn’t alone in its flexible plastic recycling journey, and there’s plenty we can learn from countries that have already cracked the code.

Germany, for example, is leading the pack. With their super-efficient deposit return system (DRS), they’ve drastically cut plastic waste. Germans return plastic bottles like it’s second nature, and their recycling infrastructure is so advanced, it can sort and process even tricky flexible plastics more efficiently.

Meanwhile, in Japan, the focus is all about education and precision. Japanese citizens are sorting champions, meticulously separating their waste into different categories. This makes recycling flexible plastics way easier for processing facilities. And to top it off, they’ve invested in cutting-edge recycling technology, like pyrolysis, which turns flexible plastics into reusable oil.

These countries prove that a combination of smart incentives, public awareness, and tech investments can make a huge difference. So, what’s stopping the rest of us from following their lead?

What consumer goods brands can do to cut down on plastic waste

Consumer goods companies are the real power players when it comes to reducing the environmental impact of flexible plastics. Here are a few ways they can help turn the tide:

Design smarter packaging: Start using materials that are easier to recycle, like mono-layer plastics, instead of complicated multi-layer ones.

Cut back on plastic: Explore alternatives like biodegradable materials or just plain old reducing the amount of plastic used in packaging.

Invest in recycling: Team up with recycling companies and back new technologies (like chemical recycling) to make the process more effective.

Educate consumers: Help people understand how to properly recycle flexible plastics—label the packaging clearly and run campaigns that make it simple to follow.

Embrace the circular economy: Create packaging that’s built to be reused or recycled, keeping materials in circulation instead of sending them to landfills.

Collaborate: New initiatives, such as the Flexible Plastic Fund founded by Ecosurety in collaboration with Mars, Mondelēz International, Nestlé, Pepsico and Unilever. The Fund’s aim is to help create an efficient system that incentivises high-quality recycling.

In the end, flexible plastics might be tricky, but they’re not unbeatable. With a little creativity, smarter systems, and a whole lot of teamwork, we can turn the tide on plastic waste.

> Follow up with…

Report: Flexible Plastic Fund FlexCollect Project Interim Report

Roadmap: Creating a Circular Economy for Flexible Plastic Packaging, WRAP

> Last week in consumer goods x climate…

The Good(s) News

»Up and coming brands

🎯 neat, the London-based cleaning supplies company that are offering alternatives to single-use plastic items, have joined the BUY WOMEN BUILT (BWB) community. BWB is a campaign encouraging consumers to support female-founded businesses, aiming to boost the UK economy and promote socially conscious shopping.

🎯 Wicklow Wolf Brewing Company and Dashel Cycle Helmets announced they are both B Corp certified!

»Bigger organisations

⭐ Fashion brands, Mulberry and Seasalt also announced that they are B Corp certified, achieving scores of 87.1 and 100.2, respectively.

⭐ Players in the hospitality, wine, spirits, and design industries - such as Rockwell Group, Amorim, BlueWell, and Southern Glazer’s Wine & Spirits have formed the Cork Collective. The collective will focus on recycling and repurposing natural cork stoppers. By using cork for projects like playgrounds, the initiative aims to promote a circular economy and reduce waste. Launched in New York City, it plans to expand nationwide, supporting renewable resources and community revitalization.

Want good news sooner? We post our top 5 stories in our LinkedIn newsletter every Friday! If your CPG brand has good news to share, let us know.👇

> We’re Curious!

Want more? Hang tight for ‘The Check-Out’ this Thursday for the latest brands in our basket. In the meantime, if you have any topics that you would like us to dig into, ping us an email on info@followingthefootprints.com to say hi!

Much love,

Team FTF